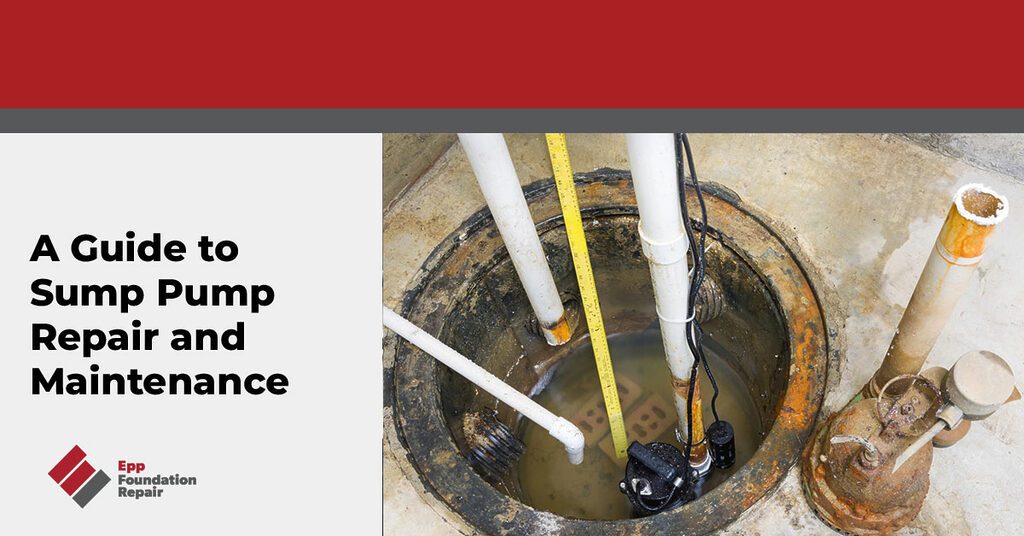

A sump pump is essential to a basement and crawl space waterproofing system. However, sump pumps require routine maintenance and, at times, repairs. Find out the main components of a sump pump, how to troubleshoot issues, standard sump pump repair methods, maintenance strategies, and when your sump pump needs to be replaced.

How Does a Sump Pump Work?

Sump pumps are usually part of a drain tile system that carries groundwater to the sump pit, and the pump ejects the water away from your home’s foundation. But do you know how the pump works? Understanding the essential components and their purpose will help you troubleshoot any problems in the future.

- Sump Pit – The sump pump is installed in a sump pit or basin and dug into the ground below the basement floor, crawl space, or in a low-lying area prone to flooding. The sump pit collects water entering the space through the drain tile system.

- Float Switch – Similar to the floating mechanism in your toilet, the float switch floats on the water surface inside the sump pit. As the water level rises, the float switch rises. Once the water level reaches a specific point, the float triggers the pump to turn on and eject the water. The float will fall once the water drains, switching off the pump.

- Motor and Impeller – Once activated, the sump pump motor starts running, and the impeller, a rotating component inside the pump, begins to spin. The impeller creates a centrifugal force that draws water into the pump.

- Discharge Pipe – Water is forced out of the pump through a discharge pipe or hose to a safe location away from the foundation.

- Check Valve – A check valve is installed in the discharge pipe to prevent water from flowing back into the sump basin once the pump shuts off. The valve helps maintain the system’s integrity and prevents unnecessary pump cycling.

- Battery Backup – Some sump pump systems may include a backup power source, such as a battery backup or generator, to ensure continued operation during power outages.

Sump Pump Troubleshooting and Repairs

Now that you have a basic understanding of the different sump pump parts, troubleshooting any problems and determining the appropriate repairs will be easier. Consider the following common scenarios:

Scenario 1: The sump pump will not turn on.

This could signal three potential causes – power failure, a damaged float switch, or a jammed impeller. A sump pump requires electricity or a battery to run. If there is a problem with the outlet or you do not have a backup power supply, you may have just found the problem. If the power is working, test the float switch by lifting it manually and seeing if it triggers the machine to turn on. If the problem is not the power or the switch, try turning off the pump and cleaning the impeller and the screen beneath it. If none of those repairs work, the sump pump may need to be replaced.

Scenario 2: The sump pump turns on but doesn’t eject the water.

In this case, the problem likely lies with the impeller, the check valve, or the discharge pipe. Turn off your pump and check your impeller to ensure the blades are in good condition. Next, look at the check valve and ensure it was installed in the right direction and is not stuck. Lastly, ensure your discharge pipe is free of debris and leaks and has not frozen over.

Scenario 3: The sump pump is running continuously.

This could mean one of two things: the float switch is positioned incorrectly, or the pump is not strong enough to handle the amount of water collecting in your drainage system. The float switch will turn on with the slightest amount of water if the float switch is too low. If the pit seems to fill up constantly, but the pump is working smoothly, the pump may be too small and you will need an upgrade.

Scenario 4: The sump pump turns on or off too soon or too late.

Any timing issues with your sump pump turning on or off are likely a float switch problem. If the sump pump turns off before all the water is removed, it turns on when there is only a little water in the pit, or the pump does not turn on soon enough, you may need to readjust the float switch to sit lower or higher. Instructions are available in your sump pump’s instruction manual.

Scenario 5: The sump pump is making strange noises.

If the sound of your sump pump has changed from a low hum to an unusually loud noise, there may be a problem with the impeller, the discharge pipe, or the check valve. A loud hum may signal a clogged or frozen discharge pump. A sudden banging may require you to secure your discharge pipe so it doesn’t move while the pump is on. A grinding sound points to a jammed impeller. A gurgling noise is usually traced to the check valve and can be exchanged for a quieter model.

How to Maintain a Sump Pump

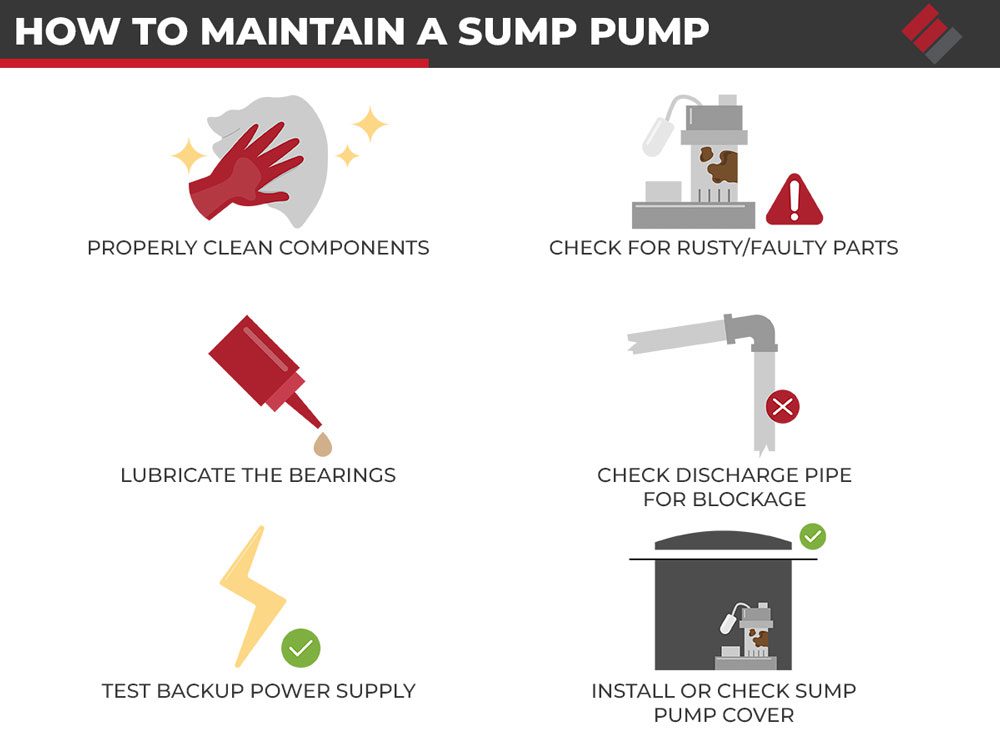

Maintaining your sump pump will minimize the need for repairs and maximize the pump’s longevity. It is recommended that a homeowner perform an annual maintenance check on their sump pump. However, sump pumps that run frequently should be monitored more closely and serviced every three to four months. Testing your sump pump before a major storm is also good practice to ensure functionality and prevent flooding. A good maintenance routine includes the following:

- Unplug the sump pump and thoroughly clean all of the components. Remove any standing water, dirt, and debris. Use a soft cloth to clean the housing, a wire brush for the inlet screen, and a plumbing snake for the discharge pipe. You can also pour a 1:1 ratio of water and vinegar into the pit to help remove any grime buildup.

- Check for any rusty or faulty parts. Ensure the blades in the impeller are in good condition and there is no visible rust on any other pump parts. To check for defective parts, pour about five gallons of water into the pit until the pump turns on and ensure it runs smoothly with no unusual sounds. If the pump has tilted, level and brace it.

- Lubricate the bearings. Please refer to your user manual for instructions since every pump is different, and some do not require lubrication.

- Check your discharge pipe to ensure the free flow of water and that it is deposited in the right place. Repair any leaks and secure the pipe if it has shifted.

- Test your backup power supply. Unplug your sump pump or turn off the power at the breaker. Then, fill up the sump pit. Ensure that the pump still turns on and ejects the water. Otherwise, you may be at risk of flooding during the next storm.

- Install or check the sump pump cover. Installing a cover and ensuring it is still in good condition will prevent debris buildup. The cover promotes optimal functionality and makes maintenance a breeze.

While you can perform the annual maintenance yourself, it is recommended that you have an annual professional inspection since their expertise and specialized tools better equip them to catch problems early and provide a more thorough cleaning.

When Is a Sump Pump beyond Repair?

Depending on use, a sump pump’s life expectancy ranges from seven to ten years. With that in mind, if you are experiencing recurring issues with your sump pump and it is seven to ten years old, it is best to replace it. We recommend placing a sticker or writing on your sump the installation date so you can keep track of its age.

If you have already checked all the parts of your sump pump and cannot narrow down the problem, it is best to have a professional inspection before writing the pump off as a dud. However, some common signs that your pump needs replacement are:

- The pump has extensive rust.

- The pump doesn’t turn on despite having power and no debris.

- The pump is constantly clogging.

- The pump continually vibrates.

- The pump turns on and off at seemingly random intervals.

It is also essential to compare the remaining life span of the pump with the cost of repairs. For instance, if the pump is over five years old, it is already approaching or has surpassed half its lifespan. In that case, you must decide if the repair cost is better spent investing in a new sump pump. If your sump pump has repeated failures, replacing the pump with a more reliable model is usually recommended. A professional can help you make that decision.

If you want to install a sump pump system in your basement or crawl space or your sump pump is having issues, schedule an appointment with us today. We also provide numerous other waterproofing solutions for your foundation. Our experts service Nebraska and parts of Iowa, Kansas, and Missouri.