Concrete is a sturdy, reliable building material, so some may wonder if sealing it is worth the money or just a sales gimmick. Interestingly, despite concrete’s known durability, its porous nature makes it susceptible to spalling, cracking, and staining. Concrete sealing involves coating a concrete surface to protect it from such damage. In this article, we will provide a list of benefits that make concrete sealing worth it and a description of the different types of sealants, how they are applied, and how they are maintained.

What are the benefits of sealing your concrete?

Sealing concrete offers several benefits, both aesthetic and practical. Concrete sealants protect your driveway, sidewalk, patio, garage floor, and other surfaces from moisture, chemicals, stains, and wear while providing various finishes. Here are some of the critical advantages of sealing concrete surfaces:

- Protection from Moisture – Sealing concrete creates a protective barrier that helps prevent water from penetrating the concrete’s pores. Sealing thus helps avoid spalling, cracking, and freeze-thaw damage.

- Stain Resistance and Easier Maintenance – Sealed concrete surfaces are less susceptible to staining from oil, grease, chemicals, and other substances. The sealer forms a barrier that repels liquids and resists dirt, dust, and grime buildup. The smooth, non-porous surface makes regular maintenance tasks such as sweeping, mopping, and pressure washing more efficient and effective.

- Enhanced Durability – Sealing concrete can improve its durability by increasing resistance to abrasion, wear, and surface damage. This is particularly beneficial for high-traffic areas.

- UV Protection – Some concrete sealers contain UV inhibitors that help protect the concrete from the damaging effects of sunlight exposure, such as fading, discoloration, and surface degradation.

- Prevention of Efflorescence – Efflorescence is a white, powdery deposit that forms on concrete due to mineral-rich water rising to the surface. Sealing concrete helps to prevent efflorescence by reducing water penetration and minimizing the leaching of minerals to the surface.

- Enhanced Appearance – Sealing concrete can improve its appearance by providing a glossy, satin, or matte finish that highlights the natural color and texture of the concrete. Sealed surfaces are more uniform and attractive, making them ideal for decorative concrete applications such as stamped concrete, colored concrete, and exposed aggregate.

While you are never obligated to seal your concrete, sealing it is a cost-effective way to improve its longevity, appearance, and performance while reducing maintenance requirements. Please keep in mind that the specific benefits of sealing concrete may vary depending on factors such as the type of sealer used, the application method, and the original condition of the concrete surface.

What are the different types of concrete sealants?

Several types of concrete sealants are available, each with its own characteristics and applications. When choosing a concrete sealer, it is essential to consider whether the concrete surface is indoors or outdoors, the amount of traffic the area receives, the desired appearance, and the level of protection required.

Acrylic Sealants

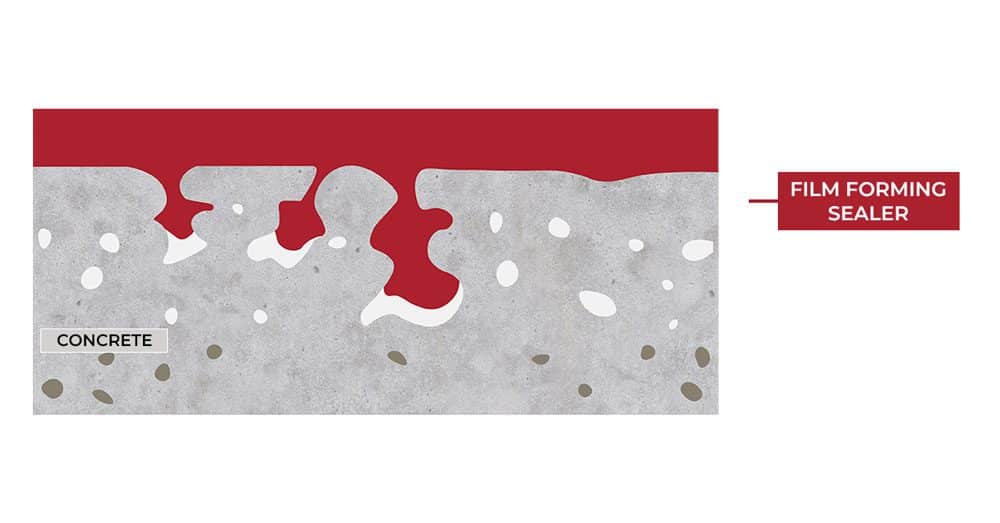

Acrylic sealers form a thin protective film on the surface of the concrete, enhancing its appearance and providing moderate protection against moisture, stains, deicing salts, chlorine, and UV damage. They are available in water and solvent-based formulas and come in various sheen levels, including gloss, satin, and matte. Acrylic sealers are suitable for decorative concrete surfaces such as stamped concrete, colored concrete, and exposed aggregate. They are commonly used for interior floors, driveways, patios, sidewalks, and pool decks. They are also amongst the most affordable concrete sealing options available.

Epoxy Sealants

Epoxy sealers consist of epoxy resins and hardeners that chemically react to form a strong, durable coating on the concrete surface. They provide superior protection to acrylic sealants against stains, abrasion, and chemical damage, making them ideal for indoor concrete surfaces like garage, basement, warehouse, and industrial floors. Epoxy sealers are available in clear and pigmented colors and can be applied with a high-gloss or satin finish.

Polyurethane Sealants

Similar to epoxy sealers, polyurethane sealants offer a high level of durability and chemical resistance, making them suitable for high-traffic areas and industrial applications. They are twice as thick as acrylic sealers and more flexible than epoxy sealants, making them tougher against scratches and abrasion. The tough, glossy finish also resists oil, grease, and chemical staining. Polyurethane sealers are available in solvent- and water-based formulas and can be used on interior and exterior concrete surfaces.

Penetrating Sealants

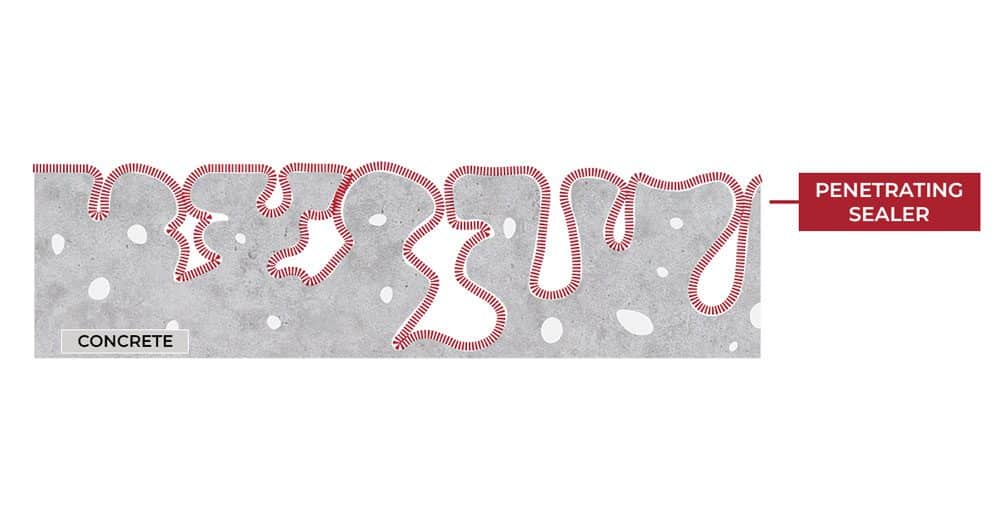

Penetrating or impregnating sealers penetrate the concrete’s pores, forming a chemical barrier that repels water, oil, and other liquids while allowing the concrete to breathe. They do not significantly alter the appearance of the concrete surface, which is ideal for individuals who want to maintain the original color of their concrete surface. Penetrating sealers suit interior and exterior concrete surfaces, including driveways, sidewalks, and garage floors. They are particularly effective for protecting against freeze-thaw damage and salt damage in areas with harsh climates.

Silicate sealers, a type of penetrating sealant, densify or harden the concrete by filling the pores of the concrete and reacting with the calcium hydroxide in the concrete. Silicate sealers make the concrete more resistant to abrasion, dust, and moisture penetration. One popular option is DensiCrete, which provides a permanent moisture barrier to the top of the concrete after one complete application.

How do you seal concrete?

Concrete sealing requires skill and experience in prepping, timing, and application to ensure effective coating and to avoid damaging the concrete or other nearby surfaces. It is best to leave concrete sealing to professionals so that you are guaranteed to end up with a lasting, attractive finish. The sealing process can be divided into three phases – prep, seal, and set.

1. Prep

Sealing is weather-sensitive, so it must be done during the appropriate conditions to ensure a proper coating and avoid staining other surfaces like windows or cars. The temperature should be between 50° F and 80° F, it should not be windy, and there should be no rain at least a day before and a few days after the application.

Before starting, it is imperative to clean the concrete surface thoroughly. That involves removing any existing sealers, stains, or debris. The concrete should also be level, and any cracks should be sealed. One quick and effective way to lift and level concrete is polyjacking. Lastly, the seams must be regrouted and surrounding surfaces covered to avoid staining anything other than the concrete.

2. Seal

Once the concrete is prepped and dry, the sealer can be applied. Following the manufacturer’s recommendations is vital since each product is unique. Sealants are typically rolled on like paint or sprayed and require at least two coats, applied in opposite directions.

3. Set

After the final coat has been applied, it is time to let the sealer dry for the recommended amount of time. Some sealers only require a few hours to set, while others require a few days. However, regardless of the sealant used, adhering to the manufacturer’s instructions and avoiding contact with water or traffic is crucial.

How do you maintain sealed concrete?

Sealing your concrete is a great way to protect it from staining and damage, but it still requires maintenance for full benefits. Try the following methods to maximize your sealant’s longevity:

- To remove dust and grime, try using a blower or soft broom.

- Clean spills as soon as possible with a gentle cleaner, 7-7.5PH, water, and a clean mop or gentle scrubbing pad.

- Reseal your concrete at the manufacturer-recommended intervals.

Contact us today to schedule a free estimate if you’re considering sealing your concrete. We also offer polyjacking and other concrete repair services to provide the most holistic service possible. Our experts service Nebraska and parts of Iowa, Kansas, and Missouri.