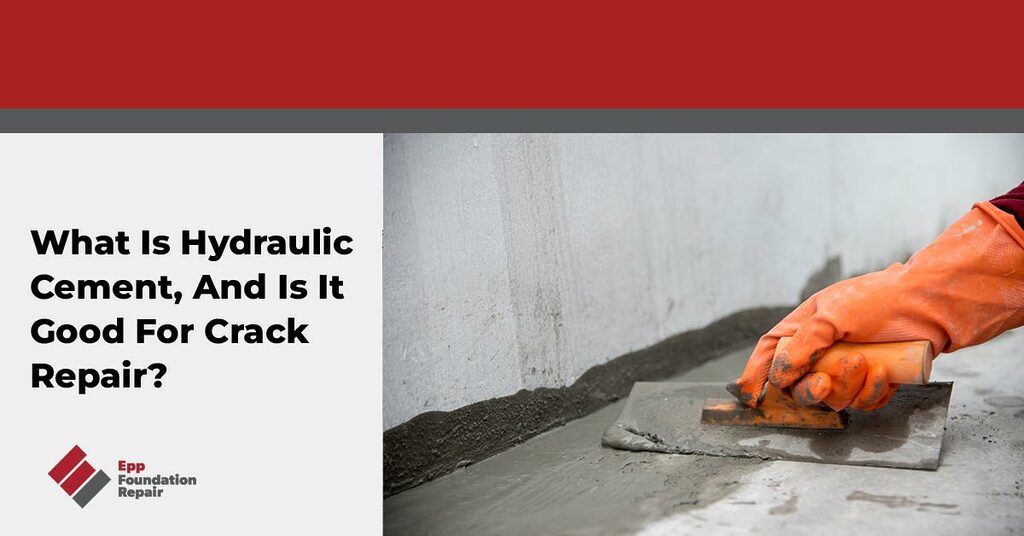

When it comes to home repairs, especially dealing with threatening cracks in foundations and walls, homeowners often wonder if there’s a quick, reliable solution. Hydraulic cement has been championed as a superhero in concrete and masonry work. But what is hydraulic cement, and is it truly effective for crack repair? Let’s explore this in detail and see if this mighty material suits your home repair needs.

What Is Hydraulic Cement?

Hydraulic cement is a specialized type of cement that sets and hardens when combined with water, creating a robust and durable bond. This type of cement is renowned for its ability to set quickly, even underwater, making it ideal for construction projects that require a rapid, strong, and water-resistant material. Its unique properties stem from chemical reactions that occur upon contact with water, forming a solid, impermeable mass that can withstand significant stress and pressure. Its versatility and reliability make it a critical component in modern construction and repair.

What Is The Difference Between Hydraulic And Regular Cement?

Hydraulic cement is designed to work well in wet conditions, allowing it to set and become firm under water or even in moist environments. This property is beneficial for repairing leaks and cracks in damp areas such as basements, foundations, and underwater structures. On the contrary, regular or Portland cement needs dry conditions to cure and harden properly.

While versatile, regular cement lacks the quick-setting and water-resistant properties of hydraulic cement. It typically has a slower curing time and is best suited for above-ground applications where moisture is not a factor. Hydraulic cement usually contains additives that enhance its quick-setting and water-resistant characteristics. In contrast, regular cement relies primarily on the gradual hydration of its components over time to gain strength. Consequently, the choice between hydraulic and regular cement often comes down to the specific environmental conditions and construction or repair project requirements.

Is Hydraulic Cement As Strong As Concrete?

Determining whether hydraulic cement or concrete is stronger depends on their applications. Concrete, a mix of cement, aggregates, and water, is known for its high compressive strength and durability, ideal for long-term projects like buildings and bridges. Its strength increases over time as it cures.

Hydraulic cement, however, sets quickly and is highly water-resistant, making it suitable for urgent repairs and sealing in wet conditions. While it forms a strong bond fast, it doesn’t match concrete’s long-term strength. Choosing between them depends on the project’s needs, environment, curing time, and structural demands.

Types Of Hydraulic Cement

Hydraulic cement comes in various types, each designed for specific applications. Some common types include:

- General Hydraulic Cement: This is the standard form of hydraulic cement without specialized additives. Used for home, building, and structural repairs, it effectively seals cracks in basements, floors, outdoor walkways, and around pipes, making it water-resistant once hardened.

- White Hydraulic Cement: This is identical in function to standard hydraulic cement but contains less magnesium and iron, giving it a white color. It is ideal for aesthetic projects where a lighter appearance is desired.

- High Early Strength Hydraulic Cement: This reduces the curing time from about a month to roughly a week. It is perfect for projects needing a quick turnaround, as it reaches full strength faster.

- Moderate and Low Heat Hydration Hydraulic Cement: Produces less heat during curing, reducing the risk of cracks in large structures like foundations and high retaining walls.

- Moderate and High Sulfate-Resistant Hydraulic Cement: This cement contains chlorides to withstand sulfates in water or soil, preventing uneven expansion and cracking. It is helpful for coastal structures exposed to higher water content.

What Is Hydraulic Cement Used For?

Hydraulic cement is versatile and finds applications in various home repair and construction projects. Some of its common uses include:

- Sealing Leaks – Ideal for patching leaks in basements and other wet areas.

- Repairing Foundations – Used to fix cracks and holes in concrete foundations.

- Waterproofing – This creates a moisture-resistant barrier in structures exposed to water.

The versatility of hydraulic cement allows it to be utilized in numerous applications, making it ideal for tasks such as:

- Foundations

- Basement Walls

- Chimneys

- Drainage Systems

- Pools and Ponds

- Cisterns

- Piers

- Tunnels

- Docks and Dams

- Elevator Pit

Pros And Cons Of Hydraulic Cement

Like any material, hydraulic cement has its advantages and disadvantages. Understanding these can help homeowners make an informed decision.

Pros

- Quick Setting – Cures rapidly, reducing downtime for repairs.

- Water Resistance – Sets even in wet conditions, ideal for leak-prone areas.

- Durable – Provides a long-lasting solution for many repair needs.

- Inexpensive – Relatively affordable compared to other repair options.

Cons

- Limited Work Time – The quick-setting nature (10-30 minutes) means you have to work fast.

- Not Ideal for Structural Repairs – Better suited for minor repairs rather than major structural issues.

- Surface Preparation – Requires thorough cleaning and preparation of the repair area for optimal results.

- Prone to Cracking – Not suitable for areas exposed to significant thermal or structural stress.

Should You Use Hydraulic Cement For Foundation Crack Repair?

Foundation cracks are a common concern for homeowners. While hydraulic cement seems like a quick fix, it’s essential to consider whether it’s the best option for your specific situation. DIY enthusiasts commonly use hydraulic cement to repair hairline cracks. Its quick-setting nature and ease of use make it a popular choice for minor repairs. Despite its popularity for minor fixes, professionals often advise against using hydraulic cement for significant foundation issues.

Hydraulic cement has several limitations that make it less ideal for foundation repair. While convenient, its quick-setting nature does not allow much time for precise application, which can result in incomplete or superficial sealing. Additionally, once cured, hydraulic cement is rigid, making it susceptible to thermal or structural stress cracking. This lack of flexibility means it may only provide a temporary fix, requiring future repairs.

Professional foundation crack repair services leverage advanced techniques and materials that go beyond the capabilities of hydraulic cement. One significant advantage of professional repairs is access to specialized materials like epoxy resin injections, which offer superior flexibility and long-lasting performance. These materials can penetrate deeper into cracks, providing a more robust, waterproof seal that moves with the natural expansion and contraction of your home’s foundation.

Moreover, professional repair services often include a thorough assessment of the underlying causes of foundation cracks. Experts can address issues such as soil settlement, water drainage problems, or structural weaknesses that might not be apparent to the untrained eye. By tackling the root causes, professionals help prevent future cracks and potential damage, ensuring your home’s long-term stability. Lastly, reputable foundation repair companies will guarantee their services, granting you peace of mind compared to any DIY solution.

Best Foundation Crack Repair Methods

When it comes to foundation crack repair, professionals recommend several proven methods for lasting results. These include:

- Epoxy Injection: Epoxy injection involves injecting a waterproof epoxy resin directly into the crack within the foundation. This method is highly effective for addressing structural cracks, as it not only seals the crack but also restores the foundation’s original strength and integrity. Epoxy injection is used in residential and commercial structures to ensure longevity and durability.

- Xypex Crack Repair: Xypex crack repair utilizes a unique crystalline waterproofing compound that reacts with the minerals in concrete to form insoluble crystals. These crystals penetrate deep into the crack and create a permanent seal that prevents water from entering the foundation. Once applied, the compound migrates through the capillary tracts in the concrete, forming a crystalline structure that blocks water pathways. This method is particularly advantageous for its ability to self-heal small cracks over time, providing continuous protection against water infiltration and enhancing the overall durability of the foundation.

- Wall Clay Process: The wall clay process involves using a specialized clay-based product to seal foundation cracks and prevent water penetration from the home’s exterior. The process starts by exposing and thoroughly cleaning the crack. A layer of tar is placed on the crack, followed by the clay-based material, which expands upon contact with water, sealing the crack effectively. This eco-friendly option is favored for its natural composition and minimal environmental impact. The clay creates a flexible yet durable barrier that can adapt to slight movements in the foundation, ensuring a long-lasting solution for foundation repairs.

Are you curious about the best approach for your foundation cracks? Contact our experts for a free, personalized assessment and repair quote. We have decades of experience and happily service customers throughout Nebraska, Kansas, Iowa, and Missouri.