Control and expansion joints are more than just lines in your pavement; they help prevent unsightly and possibly damaging cracks. Though both control and expansion joints in concrete are vital for durability, they serve distinct roles.

Understanding Control Joints In Concrete

When laying concrete for projects like sidewalks, driveways, or patios, experts strategically place control joints in concrete to guide any possible cracking.

Control joints ensure the concrete handles temperature changes and drying without compromising the aesthetics or structural integrity. This is a proactive measure that keeps the concrete safe from cracks and extends the concrete’s lifespan by effectively managing stress points.

Control joints are a critical part of concrete installation, and their effectiveness hinges on their proper depth and spacing.

Top 3 Benefits Of Control Joints In Concrete

- Prevent Random Cracking: Control joints help avoid cracks in concrete. Experts predetermine the slab’s weakest points, and the control joints encourage cracks to form in these areas rather than randomly across the surface.

- Enhance Durability: As the concrete hardens and dries, it naturally shrinks, leading to tension that causes cracking. Control joints also boost the durability of the concrete by managing internal stresses caused by temperature changes and shrinkage.

- Budget-Friendly Maintenance: Include control joints in concrete installation to reduce maintenance costs over time. Since control joints help to manage and minimize cracking, you won’t have to deal with frequent repairs and costly maintenance.

Understanding Expansion Joints In Concrete

Gaps intentionally created in concrete structures and then filled with a flexible material that absorbs the concrete’s movement are called “expansion joints.”

Expansion joints allow the concrete to expand and contract without causing damage or stress to the concrete itself or the surrounding structures.

What Are The Differences Between Control Joints And Expansion Joints?

Control and expansion joints are essential for keeping things intact, whether dealing with a personal driveway or a major highway. Here’s a full breakdown of how these joint types differ and why both are useful.

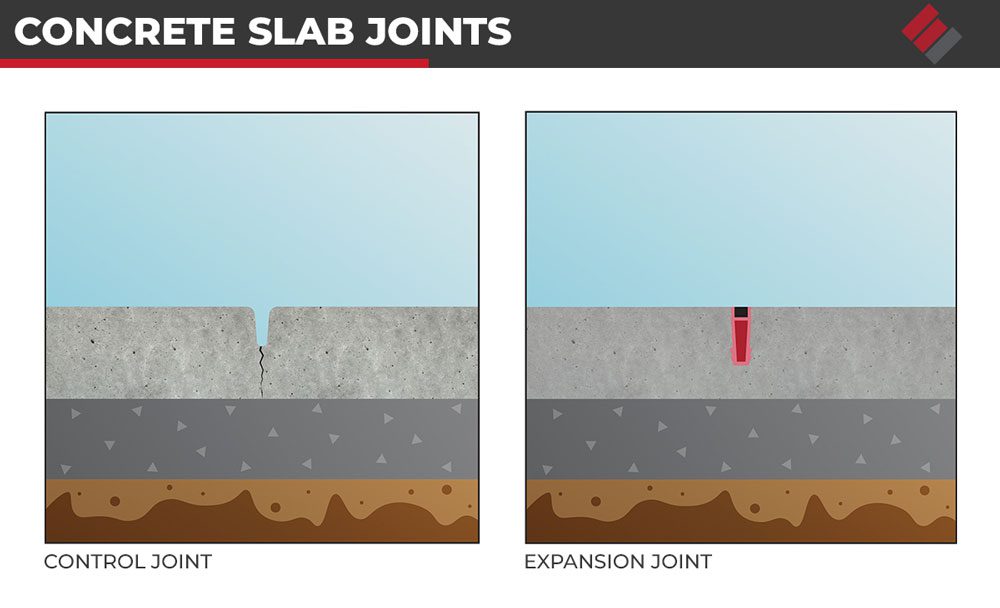

Differences In Purpose And Function

Control joints are “planned points” where the concrete is expected to crack as it cures and reacts to changes in temperature. The idea is to control where the cracks happen, preventing them from randomly marring the surface and weakening the structure.

Expansion joints tackle the problem of expansion and contraction of concrete. Expansion joints are created to absorb the pressure that builds up when the concrete expands. They prevent the pressure from pushing aggressively against anything nearby, such as other slabs, possibly causing damage.

Differences In Placement

Experts place control joints into the concrete at carefully calculated intervals, while expansion joints are placed between different sections of concrete or where the concrete meets another structure.

Different Materials Used

For control joints, some experts include materials like plastic strips to act as pre-planned weak spots. Expansion joints contain compressible and flexible fillers such as rubber.

Which Is Better: Control Joints Or Expansion Joints?

Choosing between control joints and expansion joints isn’t about which one is better—it’s about your project’s needs and goals. Control joints are used in smaller projects, such as residential floors or sidewalks, where the main concerns are managing concrete shrinkage and minor temperature shifts.

Expansion joints tackle movement on a larger scale. They’re essential for immense structures like roadways and bridges where the temperature changes can cause significant expansion and contraction of concrete.

Each joint type is critical in ensuring that whatever you build stands the test of time.

Best Practices For Concrete Joint Placement

Do you want to place concrete joints in concrete, but you’re unsure where to start? Discuss your needs and project goals with a professional. A professional foundation contractor can help you reach your goals faster, with enduring results and precision. Here is a closer look at the best practices for concrete joint placement.

Plan The Joint Layout Early

Begin planning the joint layout during the initial design phase of your project. This will ensure the joint placement is integrated into the overall structure and aesthetic plans. Consider the dimensions of the concrete area, the environmental conditions, and the expected load.

Choose The Proper Joint Type

Decide whether expansion joints, control joints, or both are necessary for your project. Remember, you would use control joints to manage shrinkage cracking and expansion joints for different parts of the structure where movement or expansion may happen.

Determine Proper Spacing And Depth

Consider the spacing and depth of expansion and control joints in concrete to ensure maximum efficacy. We suggest consulting with a professional foundation repair service for the most accurate information based on your project’s needs.

Use The Best Materials

If you’re using expansion joints, you’ll want to consider sturdy materials such as rubber and asphalt-impregnated fiber strips. Pre-molded joint fillers are also an excellent option.

It’s All About Timely Execution

If you’re using control joints, the cutting time is crucial. Cut the joints as soon as the concrete has set enough but before it becomes too hard to cut. Typically, cutting the joints within the first 6 to 18 hours after pouring is best. Finally, maintain the joints by ensuring they are adequately sealed and debris-free.

FAQ

What Should I Consider When Installing Expansion Joints?

Before installing expansion joints, consider these four factors: location, materials used, spacing, and integration with building design. Always place expansion joints where you expect movement between separate parts of a structure.

Use flexible and durable materials to accommodate expansion and contraction without loss of cohesion.

Can You Have Too Many Joints In Concrete?

Yes, you can have too many joints in concrete—using more than necessary can backfire! If you go overboard and segment the concrete excessively with joints, you may compromise its overall strength.

Try to find a balance: enough joints to prevent cracking but not so many that you weaken the structure.

What Is The Main Difference Between Control Joints And Expansion Joints In Concrete?

The main difference between control joints and expansion joints in concrete is their purpose. Control joints are used to prevent cracking caused by shrinkage, while expansion joints are used to allow for the natural expansion and contraction of concrete due to temperature changes. By understanding the differences between these two types of joints, engineers and contractors can design and build concrete structures that are more durable, long-lasting, and resistant to damage.

Contact Us Today

Ready to ensure your concrete project stands the test of time? Contact us for expert advice on the best practices for implementing control and expansion joints. Our team of professionals is here to guide you through every step of the process, providing tailored solutions to meet your specific needs. We serve areas in Nebraska, Iowa, Kansas, and Missouri.